Learn how to choose the right mezzanine kit for your space and needs with this comprehensive buying guide.

Key takeaways:

- Mezzanine kits maximize vertical space, doubling or tripling usable floor area.

- They are cost-efficient alternatives to building expansions.

- Mezzanine kits come in different types for various needs.

- The installation process involves preparing the space and following instructions.

- Compliance with building codes and permits is essential before installation.

Definition and Purpose of Mezzanine Kits

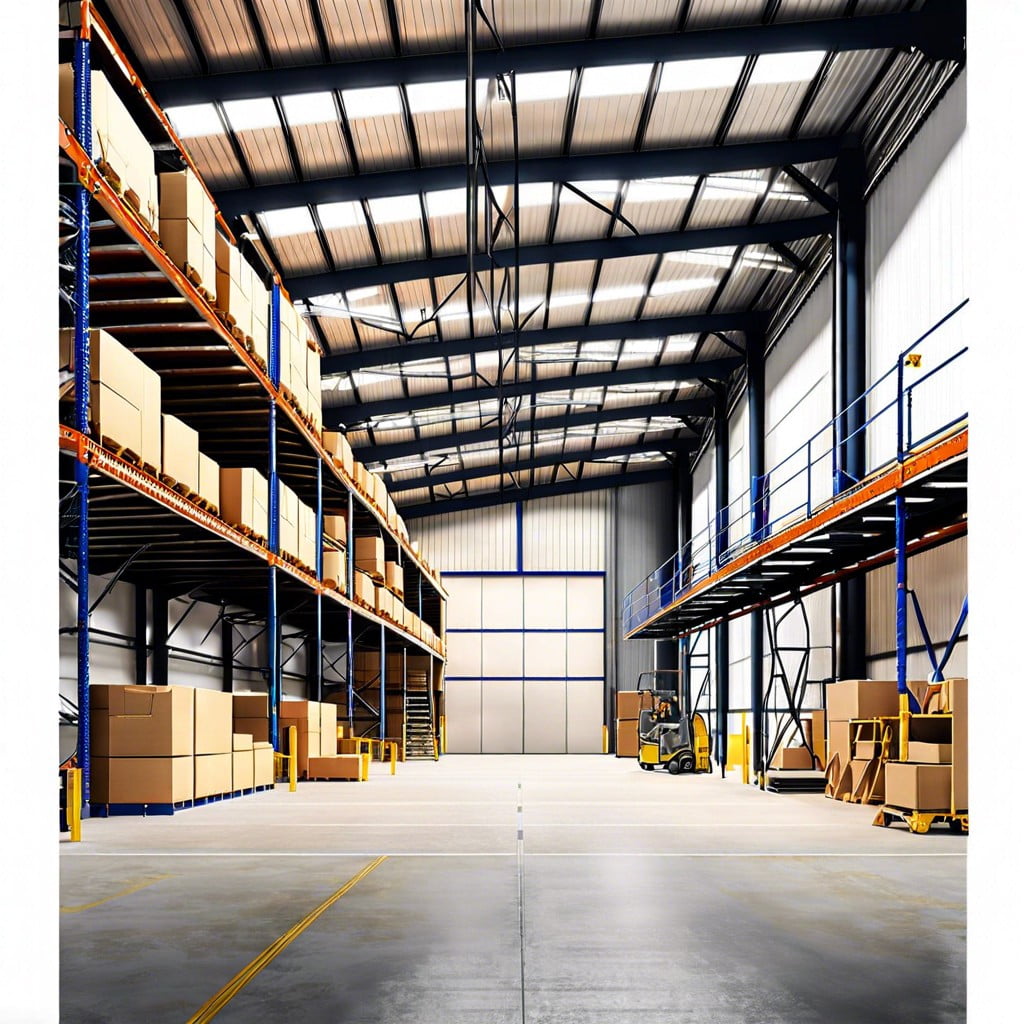

Mezzanine kits provide an elevated platform separate from the main floor in a building, typically used in industrial, warehousing, or commercial spaces. These kits serve as a cost-effective method to maximize the space within a facility. They are prefabricated, which simplifies and speeds up installation, compared to custom-built structures.

- Key points include:

- Space optimization: They maximize vertical space, effectively doubling or tripling the usable floor area.

- Flexibility: Available in various sizes and configurations, they adapt to different space requirements and purposes.

- Cost-efficient: Less expensive than building expansions and can be dismantled and relocated if necessary.

This means a business can expand its operations without the need for extensive renovations or moving to a new location, thereby saving both time and money.

Types of Mezzanine Kits

Mezzanine kits come in several forms, each suited to different needs and spaces. The most common types include free-standing, rack-supported, and shelf-supported mezzanines.

Free-standing mezzanines are versatile and widely used in various industries. They are not attached to the existing structure, allowing flexibility in location and reconfiguration. This type is ideal for adding office space or extra storage above the work floor.

Rack-supported mezzanines are integrated with pallet racking to maximize warehouse space. They provide additional storage levels and can be easily accessed with forklifts, making them perfect for high-density inventory management.

Shelf-supported mezzanines rely on shelving systems to support the floor above. This option is great for smaller items and can significantly enhance order picking efficiency by increasing the usable area without expanding the footprint.

Each type supports different weight capacities and configurations, catering to specific operational goals and physical environments. Choosing the right mezzanine kit hinges on understanding these factors and assessing the intended use and available space.

Installation Process Overview

Installing a mezzanine kit can be straightforward if you plan properly and follow these key steps:

First, check that you have all the necessary components as per the kit’s inventory list. Missing just one piece can halt the entire process.

Next, prepare your space. Ensure the floor area is clean, level, and strong enough to support additional weight. It’s vital to measure twice and cut once, as accuracy here prevents issues later.

Assemble the framework according to the manufacturer’s instructions. Typically, this involves constructing the vertical supports and horizontal beams. Tools required usually include wrenches and screwdrivers, though specifics may vary by kit.

Attach the floor decking. This step might require extra hands, so consider having a team ready. Flooring panels usually lock together and fix onto the framework.

Finally, add any accessories like stairs or handrails. These are essential for safety and must be securely attached.

Remember, while the process may vary slightly depending on the mezzanine kit brand, these general steps will guide you through to a successful installation.

Benefits of Installing a Mezzanine

Mezzanine floors can transform your space, making them a smart choice for many businesses. They effectively double or even triple the usable floor area, accommodating more operations without the need to relocate. This setup is ideal for expanding inventory space in warehouses or adding new office areas above factory floors.

Installing a mezzanine is also cost-effective compared to physical expansion. The cost of building upwards within an existing structure is significantly lower than moving to a larger facility or constructing additional buildings. This makes it an economically savvy solution, especially for businesses experiencing rapid growth.

Moreover, mezzanines enhance workspace functionality. By providing additional levels, they facilitate better organization and can be customized to fit specific operational needs. Whether it’s creating more efficient workflow patterns or separating different work areas, the flexibility of a mezzanine design adapts to various business demands.

Lastly, the installation of a mezzanine can increase property value. Adding usable square footage without altering the footprint of a building is an attractive feature that boosts overall property worth, proving beneficial if you decide to sell in the future.

Regulatory and Compliance Issues

Before diving into the installation of a mezzanine kit, it’s crucial to brush up on relevant building codes and permits. Each locale has distinct regulations aimed at ensuring safety and functionality, making compliance a necessary step.

Key considerations include:

– **Local Building Codes**: These dictate the construction standards, from materials used to the structural integrity required. Ensuring your mezzanine meets these codes prevents potential legal issues and ensures safety.

– **Permit Requirements**: Often, modifications like mezzanines require a permit. Skipping this step could lead to fines or a mandate to dismantle the structure.

– **Load Capacity**: Regulations specify how much weight your mezzanine can safely support. This is vital for both compliance and practical functionality, especially in industrial settings.

– **Fire Safety**: Some regions have specific guidelines about fire prevention measures, such as the installation of sprinklers or use of flame-retardant materials.

Navigating these issues smoothly pivots on engaging with local building authorities early in the planning stage. This proactive approach minimizes roadblocks and facilitates a smoother installation process.