Insulating a metal building is necessary to maintain temperature control, reduce energy costs, and prevent condensation, which can lead to rust and damage.

Insulating a metal building is not a requirement but it’s highly recommended for several reasons including energy efficiency, comfort, and cost savings.

If you’re considering whether or not to insulate your metal building, you’re in the right place. This article will delve into the benefits of insulation, the types of insulation suitable for metal buildings, and how to install it.

Stay with me to get a comprehensive understanding of why insulation is a wise choice for your metal building.

Key takeaways:

- Insulating a metal building is highly recommended for energy efficiency.

- Insulation stabilizes temperature, reduces moisture, and absorbs sound.

- Insulation improves energy efficiency and indoor air quality.

- Different insulation types include fiberglass, spray foam, and reflective insulation.

- Consider climate, R-value, and cost when choosing insulation.

Why Insulate A Metal Building?

The insulation of metal buildings is crucial for prolonging their lifespan and ensuring optimal functionality. It goes beyond just controlling the internal climate or reducing energy bills.

Being a great thermal conductor, metal is susceptible to extreme temperature changes. Insulation rectifies this, rendering the building suitable for year-round use. This is especially important if the building is a workspace or a place where temperature-sensitive items, like electronics or perishables, are stored.

On another note, metal buildings, by default, can be noisy due to their reverberating nature. Insulation mutes this echo, creating a quieter environment inside.

Moreover, moisture and condensation can tarnish metal – a common issue in metal structures. Insulation, by preventing moisture build-up, aids in the prevention of corrosion and rust, thereby increasing the durability of the building.

Lastly, proper insulation can improve the air quality inside the metal building by reducing dust and allergens, resulting in a healthier indoor environment.

Purposes & Benefits of Insulating a Metal Building

To begin, insulation significantly stabilizes the building’s temperature. This temperature control feature proves especially valuable in extreme climates, keeping the interior cool in summer and warm in winter. Insulation further acts as a barrier to moisture, drastically reducing the chance of rust or corrosion on your metal building. This valuable barrier also prevents the growth of mold and mildew, boosting the property’s long-term health.

In addition, insulated buildings benefit from sound absorption. Insulation dampens the transfer of noise from outside, lending to a quieter, more peaceful internal environment.

Beyond comfort, insulation can lead to significant energy savings. By maintaining temperature stability, your heating and cooling systems do not have to work as hard, thereby reducing energy consumption and cost.

The addition of insulation can also improve the indoor air quality. It creates a barrier against dust and other particles, providing a cleaner, healthier environment inside the building.

Lastly, insulating your building can increase its value. Given the many benefits, a fully insulated metal building is an attractive investment should you ever decide to sell or lease your property.

Understanding Metal Building Insulation

Metal building insulation primarily serves to regulate the internal temperature, reduce energy consumption, prevent condensation, and improve the acoustics within the space. Its effectiveness lies in the ability to restrict the transfer of heat, contributing to a consistent and comfortable indoor climate regardless of external weather conditions.

Bear in mind that thermal performance and moisture control are both vital. A suitable insulation system ensures the building maintains a comfortable temperature throughout the year, reducing reliance on heating and cooling systems and, by extension, lowering energy costs. It also plays a crucial role in preventing condensation, which can lead to corrosion and damage over time.

Don’t overlook insulation’s role in sound absorption. A well-insulated metal building can limit the transmission of exterior noise, providing a quieter, more productive environment inside.

Given these crucial points, understanding metal building insulation requires an appreciation of its multi-faceted role in enhancing the building’s efficiency, durability, and overall performance. The selected material and installation technique will influence these factors, ensuring the finished system complements the specific needs of the metal structure.

Stabilizes the Building’s Temperature

Insulation plays a crucial role in controlling the internal environment of a metal building, particularly the temperature. When a building is properly insulated, it retains heat during the colder months and reflects heat in the summer, reducing the need for excessive heating or air conditioning. This climate control capacity is especially helpful in metal buildings due to their tendency to quickly conduct heat or cold.

Insulation acts as a barrier, keeping the desired temperature inside without outside weather conditions influencing it unduly. Careful selection of insulation products can result in a comfortable indoor temperature no matter what the season, providing a better environment for people, goods, or animals inside the building.

Limits the Building’s Moisture

Proper insulation plays a crucial role in preventing the build-up of condensation within metal buildings. When temperature differences occur between the interior and the exterior, condensation forms. This poses a significant risk for such structures.

1. Rust and Corrosion: Persistent moisture can prompt rust and metal corrosion, which weakens the structural integrity of the building.

2. Mold Growth: A moist environment is an ideal breeding ground for molds. Over time, unchecked mold growth can lead to health issues for building occupants.

3. Equipment Damage: Moisture can damage equipment, stored goods, and any other delicate materials inside the building, further highlighting the need for efficient insulation.

4. Insulation Deterioration: Moisture can reduce the efficiency of certain types of insulation, leading to an overall decrease in a building’s energy efficiency.

Implementing an adequate insulation strategy is key in buffering these temperature differences and eliminating condensation, contributing to the durability and longevity of metal buildings. You can address moisture-related issues through the use of vapor retarders or barriers and by ensuring proper insulation installation to avoid gaps or seams.

Absorbs Sound

An often overlooked advantage of insulation, particularly in larger buildings such as warehouses or workshops, is its sound absorption capability. Insulation works as a buffer, reducing external noise from heavy rain on the roof, or from traffic and other environmental disturbances.

It can also minimize internal noise transfer between different areas within the building. Some common types of insulation materials known for excellent sound absorption qualities include fiberglass and spray foam.

This unique feature ensures a quieter, more comfortable environment, especially crucial in workspaces where concentration and communication are key.

Energy Efficiency

Insulating your metal building can bring tremendous energy efficiency. Without insulation, the structure will easily transmit heat, leading to higher costs to cool or heat the building. Opting for high-quality insulation reduces this thermal transfer radically and minimizes the strain on HVAC systems – thus, significantly cutting down your energy expenses.

Moreover, it significantly helps in minimizing the carbon footprint. Functioning HVAC systems at full capacity emit greenhouse gases into the atmosphere. By buffering the extreme temperatures outdoors and reducing the need for HVAC operations, insulation assists in lessening the environmental impact of your steel building.

Lastly, it contributes to occupant comfort. Alongside the energy-saving benefits, insulation ensures a more comfortable interior environment by maintaining a steady temperature regardless of the weather outside. This makes it vital for structures like office buildings where a stable and soothing environment plays a significant role in productivity.

Indoor Air Quality

Maintaining the quality of the indoor air is one of the foremost considerations when insulating your metal building. Insulation has the ability to significantly reduce the amount of dust, allergens, and other pollutants that can enter the building, providing cleaner, healthier air for occupants. It’s a crucial aspect when considering work environments or residential metal buildings, as it can have a meaningful impact on the well-being and productivity of the inhabitants.

Inadequate insulation, on the other hand, can lead to condensation on metal panels. This may support the growth of mold or mildew, detrimental conditions for indoor air quality. Further, insulation interferes with the process of heat transfer. This helps maintain an optimal indoor temperature, reducing the reliance on HVAC systems, and consequently reducing draftiness, a common issue that can affect the air you breathe indoors.

Various insulation options provide gas and vapor barriers, these do not only insulate but also significantly reduce the penetration of harmful gases such as radon and carbon monoxide. In summary, the choice of insulation for your metal building plays a crucial role in maintaining indoor air quality, providing a comfortable and more sustainable living/working environment.

Increase the Value of Your Metal Building

Proper insulation significantly enhances a structure’s worth. Foremost, it ensures the structure’s comfort and efficiency, making it more appealing to potential buyers or renters.

1. Energy Efficiency: With good insulation, the building can maintain temperature levels adequately, potentially reducing energy bills.

2. Prevent Deterioration: Insulation helps keep out moisture, reducing the risk of rust and corrosion. Metal buildings with solid insulation tend to have a longer lifespan.

3. Versatility: Insulated metal buildings are adaptable to a variety of uses, from workshops and garages to homes and businesses, expanding the potential buyer or rental market.

Investing in quality insulation can evidently result in a lucrative boost for a metal building’s value.

Types of Metal Building Wall Insulation

When selecting wall insulation, several options warrant consideration. Spray Foam Insulation, popular for its elasticity, fills cavities and crevices effortlessly, securing a tight seal against air and moisture. It can be closed-cell for extra rigidity or open-cell for the elastic finish.

Rigid Board Insulation, primarily used for external walls, provides high R-value and water resistance—ideal for cold climates.

Fiberglass Batt Insulation is also a typical choice, providing good insulation properties alongside a moisture-resistant barrier.

Lastly, consider Insulated Metal Panels, combining insulation and cladding into a single unit. Each material has its virtues depending on your specific needs.

Types Of Metal Building Roof Insulation

Fiberglass insulation is a common choice, particularly due to its fire and moisture resistance. It comes in pre-cut batts or rolls that can be easily applied between the metal building’s purlins. The glass wool’s ability to trap air makes it efficient in resisting heat flow.

Rigid Board Insulation, made from polystyrene, polyisocyanurate, or polyurethane, offer excellent heat resistance and sound absorption properties. They can be chosen based on thickness, the level of thermal resistance (R-value) required, and budget constraints.

Spray foam insulation, either open-cell or closed-cell, is an efficient yet expensive option. Along with good thermal insulation properties, it effectively seals nooks, corners, and crevices, providing superior air sealing properties. Open-cell spray foam is more affordable but less insulating; closed-cell foam is pricier but offers excellent insulating and moisture-resisting properties.

Reflective insulation, also known as radiant barrier insulation, works by reflecting radiant heat, ideal for hotter climates. It uses a reflective surface (typically aluminum foil) to obstruct heat flow. This insulation is typically used in combination with another kind of insulation for maximum efficiency.

Remember, the choice of roof insulation should suit your specific needs correctly, considering factors like climate, budget, and building usage.

Fiberglass Solutions for Metal Buildings

Fiberglass, widely known for its heat resistance and sound absorbing properties, is an ideal insulation solution for metal buildings. A prime choice for those seeking cost-effectiveness, this material strikes a perfect balance between thermal efficiency and affordability.

Firstly, durability is a key attribute. With a high resistance to damage from heat, water, and chemicals, this robust material is well-suited for a variety of locations, from humid climates to industrial environments.

Moreover, fiberglass insulation promotes energy efficiency by effectively reducing heat transfer. This ensures comfortable indoor temperatures year-round, making fiberglass an essential addition to the energy-conscious builder’s toolkit.

Another key feature is the excellent sound absorbing capacity of fiberglass. It significantly reduces transmission of noise from both outside and within the building, providing a peaceful environment.

Lastly, this lightweight material simplifies the construction process. The easy handling and installation make fiberglass a convenient option for builders. With these attributes, it’s clear fiberglass insulation can offer powerful benefits in metal building construction.

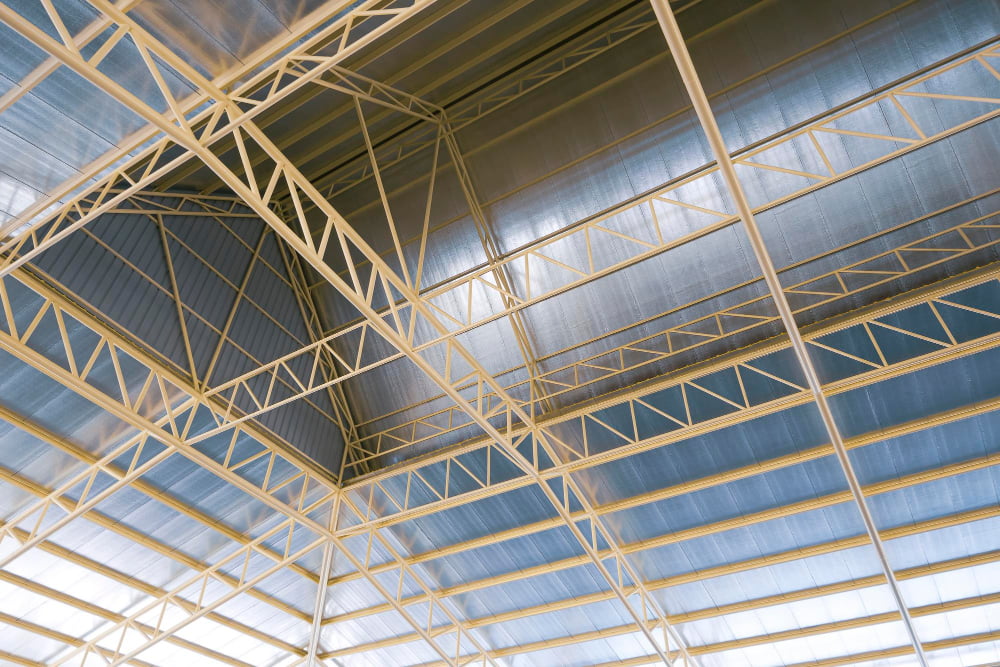

Standard Metal Building Blanket Insulation

Blanket insulation, often made of fiberglass, is arguably one of the most popular choices for metal structures. This insulation is custom fit for the metal building, minimizing gaps or compression points that could jeopardize performance. It’s rolled out between the frame’s girts and purlins before the metal panels are installed, contributing to quicker and more efficient installation.

Structures with temperature control needs can greatly benefit from this form of insulation as it effectively keeps heat transfer at bay. For regions where mild climate prevails, this might prove to be a more practical and economical choice.

Though it’s cost-effective, careful consideration should be given to its R-Value, which indicates insulation’s resistance to heat flow. The higher the R-Value, the better the insulating effectiveness. Typically, building codes will dictate the minimum R-Value needed for a structure.

One potential disadvantage, though, is its susceptibility to moisture absorption, which could lead to damage and decreased functionality over time. This can be mitigated by opting for high-quality products with vapor retarders.

Rigid Board Solutions for Metal Buildings

Made from fibrous materials or plastic foams, rigid boards offer high insulation value, making them ideal for metal buildings’ roofs, walls, and floors. These standalone rigid panels are easy to handle, cut, and install due to their robustness. They’re excellent in situations requiring significant insulation with limited space, as they provide more insulating capacity per inch than other forms.

Rigid boards effectively resist moisture and can withstand high temperatures, enhancing your metal building’s protection and lifespan. There are many types of rigid boards, like polyurethane, polystyrene, and polyiso cyanurates, each with their distinct advantages. Polyurethane and polyiso cyanurates offer superior R-value per inch, while polystyrene boards are cost-effective and provide good moisture resistance.

Despite their higher cost compared to blanket insulation, their efficiency, durability, and versatility can make rigid board solutions a worthwhile investment for your metal building insulation. They provide a smooth, clean, and aesthetically pleasing surface that can be left exposed, contributing positively to your metal building’s interior. The only caveat – make sure to adhere strictly to manufacturers’ installation guidelines to maximize its effectiveness.

Insulated Metal Panels

Insulated Metal Panels (IMPs) make for a smart choice for many developers due to their combined attributes of high-performance insulators and longevity in all weather conditions. They are essentially factory-engineered units comprising a layer of insulating foam sandwiched between two sheets of metal. The built-in insulation acts as a strong barrier against heat transmission, contributing to energy efficiency.

Another significant advantage of IMPs is their quick installation. As a single-element product, they can speed up construction schedules, saving time and budget. Plus, they provide a wide versatility of design options with a great aesthetic appeal, making them preferable for modern projects.

Furthermore, IMPs offer excellent moisture management. The metal “skin” effectively prevents water infiltration, reducing the risk of mold infestation and structural damage.

Finally, they have superior fire resistance ratings. Being metal, they effectively resist combustion while the foam core material releases very little heat, protecting the structure and occupants in case of fire occurrences.

In a nutshell, Insulated Metal Panels deliver high-quality insulation, aesthetic diversity, and impressive overall performance, enhancing the utility and viability of a variety of metal buildings.

Spray Foam Insulation for Metal Buildings

Spray foam insulation, a modern and highly efficient solution, rises in popularity due to its significant advantages. This polyurethane product expands and hardens upon application, effortlessly filling in gaps and creating a tight seal. While it’s often more costly upfront, the long-term energy savings can outweigh initial expenses.

Let’s take a closer look at some of its benefits:

- 1. Unbeatable Air-Tight Seal: The hardened foam forms a strong barrier, practically eliminating air leakage. This helps maintain a steady temperature, reducing the strain on heating and cooling systems.

- 2. Moisture and Mold Resistant: Unlike other insulation types, spray foam blocks water and moisture, thus deters mold growth—a common issue in metal buildings.

- 3. Noise Reduction: The foam’s density also provides excellent soundproofing, reducing the echo common in metal structures and blocking external noise.

- 4. Long-Lasting: Spray foam insulation tends to last longer compared to alternatives, extending the maintenance cycle for the building.

Spray foam insulation isn’t without its cons. Because of the complex process to install it and the necessary protective equipment, professional installation is highly recommended, increasing the cost. Nonetheless, many property owners find that the benefits offset these drawbacks, making spray foam an attractive option for metal building insulation.

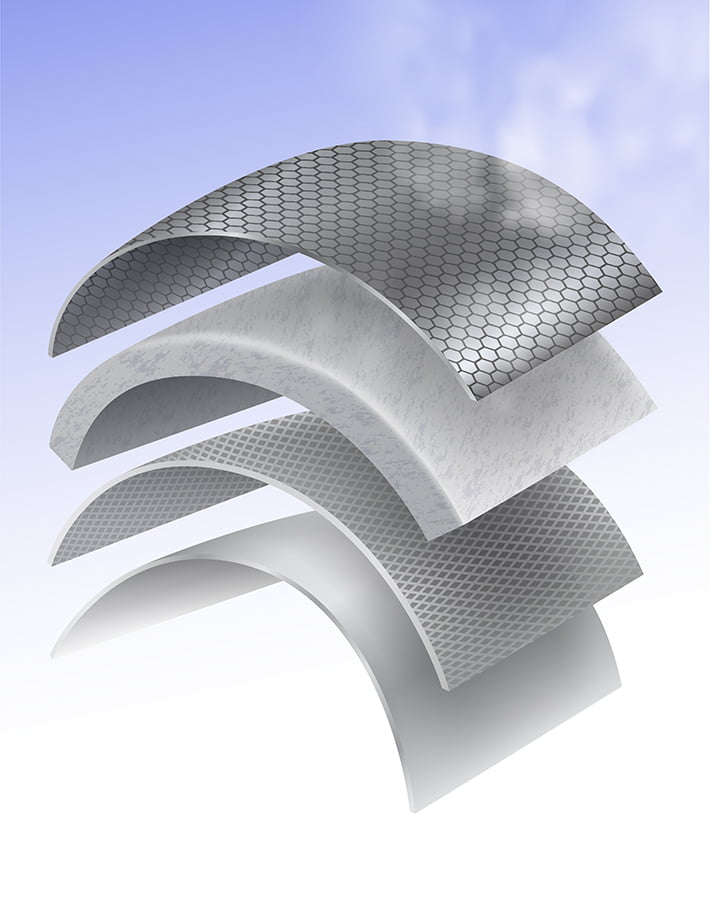

Reflective Insulation for Metal Buildings

Reflective insulation, sometimes called ‘radiant barrier’, works differently from traditional forms of insulation. Instead of hampering heat flow, it utilizes highly reflective surfaces to bounce radiant heat away, preventing it from entering the interior of the metal building. This is especially valuable in areas with high sun exposure.

This type of insulation is thin, lightweight, and easy to install. It often comes in rolls that are fit between the metal framing members, creating a barrier that reflects radiant heat. Its aluminum foil-like surface provides a double-action benefit, reflecting heat away during summer months and bouncing heat back into the building during colder seasons.

While reflective insulation provides impressive performance against radiant heat, it’s not as effective in reducing conduction or convection heat. As such, it’s often used in conjunction with other insulation types to ensure comprehensive thermal protection.

Additionally, reflective insulation is typically low in cost with top-notch durability. The material is resistant to humidity and water, which helps combat the risk of mold and mildew. Plus, it’s non-toxic, making it a safe choice. However, proper installation is crucial to maximize the benefits of reflective insulation, which may require professional expertise.

Factors to Consider for Metal Building Insulation

Several considerations may significantly impact the selection of insulation solutions.

The climate of the project location should always be a starting point. For instance, cold climates require higher R-Values to provide better thermal resistance, while hot, humid climates benefit from insulation with excellent moisture control.

R-Value, U-Value, and Perm Rating are critical indicators to consider when selecting insulation. R-Value measures thermal resistance, U-Value gauges heat transference, and Perm Rating indicates vapor permeability. Better understanding of these units boosts your insulation decision-making efficacy.

Think about the insulation type that would work best for your specific needs and circumstances. For instance, Batt and Roll insulation is typically used in unfinished walls, including foundation walls, and loose-fill insulation is perfect for difficult-to-reach areas, enclosed existing walls or irregularly shaped areas.

Ultimately, cost-effectiveness plays a significant role in the decision-making process. Balancing up-front costs, long-term energy savings, and maintenance requirements will help ensure an optimal return on investment.

In determine the best insulation for a metal building, understanding these factors will ensure an informed choice, leading to a well-insulated, energy-efficient metal structure.

R-Value, U-Value, and Perm Ratings for Metal Buildings

When classifying insulation materials for metal buildings, three key metrics come into play: R-Value, U-Value, and Perm Ratings.

R-Value is a measure of resistance to heat flow – the higher the R-value, the more substantial the insulation. Ideally, for most climates, your metal building should have insulation with an R-value ranging from R-13 to R-19 for walls and R-30 to R-38 for roofs.

On the contrary, U-Value is an indicator of heat loss, specifically how much heat can escape through an insulating material. Lower U-Values translate to better insulation and reduced energy consumption, which in turn, lowers your heating and cooling costs.

Then we have Perm Ratings, a critical measure of any insulation’s capacity to resist moisture penetration. For applications in metal buildings, using insulation material with perm rating in the range of 1.0 or less – ideally as close to 0.1 as possible – is considered effective in keeping condensation at bay. Moisture control is essential for a metal building as it can prevent structural integrity issues in the long run.

These values and ratings form the bedrock of understanding the effectiveness of different insulation choices, laying the groundwork for you to make the final decision based on cost, property location, and specific needs for your metal building’s insulation.

Different Types of Insulation: Batt and Roll, Loose-fill

Batt and roll insulation is designed out of mineral fibers, such as fiberglass or rock wool. Its flexibility and availability in various thicknesses and widths make it an ideal choice for metal buildings. By preventing thermal bridging, it increases the structure’s energy-efficiency. It’s typically installed between beams, joists, and studs.

Loose-fill insulation, on the other hand, is composed of small particles of fiber, foam, or other insulating material. These tiny particles form a blanket that can conform to any space without disturbing structures or finishes, making it perfect for hard-to-reach places within a metal building. It requires specific equipment for installation and best used in enclosed spaces like wall cavities and hard-to-reach areas.

Both types offer unique benefits based on the specific needs and construction of your metal building. By understanding the distinctions between these insulating materials, you can make informed choices to enhance your structure’s performance and longevity.

Most Cost-Effective Ways to Insulate a Metal Building

When it comes to cost-effectiveness in insulating your metal building, one needs to look at both the short term and long term benefits.

1. Insulation Blankets: These are relatively inexpensive and can be installed quite easily. They are well suited for temperature control in moderate climates.

2. Spray Foam: Although it is more expensive up front, it offers an effective air and vapour barrier, hence reducing energy costs over time.

3. Rigid board Insulation: It comes with a high insulating value per inch of thickness, making it ideal for thin walls and limited spaces.

4. Reflective Insulation: Quite inexpensive and works by reflecting radiant heat, making it especially helpful in hot climates.

5. Loose-fill insulation: While it may be a bit harder to install, it’s great for out of reach and irregularly shaped areas of your building.

Do remember though, what may seem like the most cost-effective option initially may not provide the most savings in the long run. Therefore, you need to consider the future energy cost savings against the upfront insulation cost to make the most cost-effective decision for your metal building. Always consider the specific needs and climate of your location when choosing the insulation type.

FAQ

Should you insulate a metal building?

Yes, it is beneficial to insulate a metal building to improve energy efficiency, control temperature, and prevent issues like condensation, mold and mildew growth.

What is the best thing to insulate a metal building with?

The best insulation for a metal building is fiberglass due to its cost-effectiveness, high R-value, and flexibility with various facing solutions for a durable and appealing finish.

Should I insulate my metal shed?

Yes, it’s recommended to insulate your metal shed to prevent condensation and rust, and to keep it comfortable and safe for any valuable stored items.

Is insulating a metal garage worth it?

Yes, insulating a metal garage is worthwhile as it offers substantial benefits, such as managing severe temperature swings and preventing issues like condensation, rust, corrosion, mold, and mildew.

How does the insulation of metal buildings enhance their energy efficiency?

Insulation in metal buildings enhances their energy efficiency by reducing heat transfer, thus maintaining a consistent interior temperature regardless of external weather conditions.

What are the different types of insulation suitable for metal buildings?

The different types of insulation suitable for metal buildings include fiberglass insulation, rigid foam insulation, spray foam insulation, and reflective insulation.

How does climate influence the need to insulate a metal building?

Climate significantly influences the need to insulate a metal building as colder climates demand higher insulation for heat retention while hotter climates require insulation to prevent excess heat absorption.

Related Reading:

- Does Spray Foam Insulation Work on Metal Building? – Answering Your Insulation Queries

- How Much Does it Cost to Insulate a Metal Building: Comprehensive Guide on Pricing

- Spray Foam Insulation: Benefits, Costs, and Installation Process

- How to Insulate a Metal Pole Building: Simple, Effective Techniques

- Spray Foam Insulation for Metal Buildings: Benefits and Installation Tips